Direct semiconductor lasers, helping laser heating reduce costs and improve efficiency!

04/18

2025

In 2024, China's new energy vehicle production and sales reached 12.888 million and 12.866 million units respectively, with year-on-year growth of 34.4% and 35.5%. With the global increase in electric vehicle penetration, the lithium battery market demand is huge.

In the lithium battery production process, the electrode coating process is one of the key steps, and the drying process consumes a large amount of energy (about 50%-70% of the total energy consumption in the electrode manufacturing stage). Therefore, Energy consumption optimization of the lithium battery electrode coating drying process has become a key link in cost reduction and efficiency improvement in the industry chain.

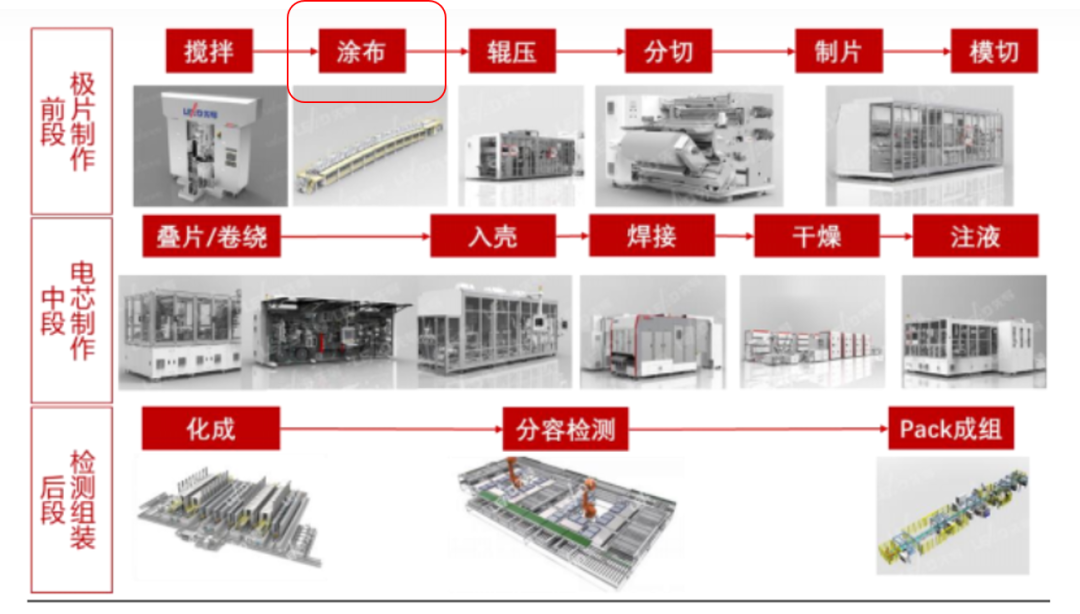

Lithium Battery Manufacturing Process

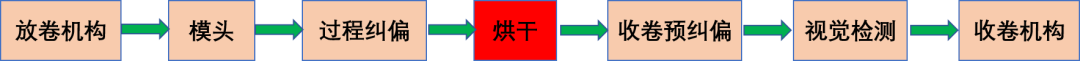

Coating Process

The substrate passes through the unwinding mechanism, and the die head evenly coats the slurry on the substrate. After drying treatment, high temperature dries the moisture in the electrode sheet. As a key node in the coating process, the baking effect directly affects the product quality of lithium batteries.

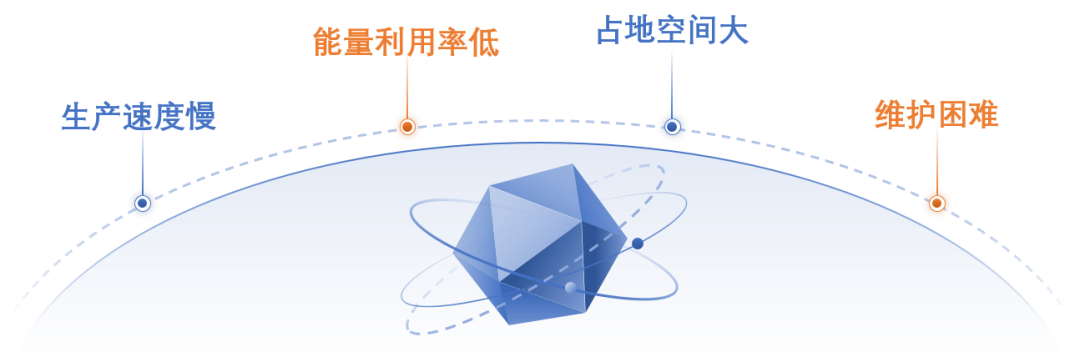

Pain points of traditional oven heating solutions

The traditional electrode drying process uses oven heating, evaporating solvents through heated air convection. However, this convection drying method has many pain points:

-

Low energy utilization: Traditional hot air drying relies on convective heat transfer, which has low heat transfer efficiency. Especially when the coating thickness increases, the internal solvent diffusion rate is limited, leading to prolonged drying time;

-

Low production efficiency: Differences in solvent evaporation rates between the coating surface and interior easily cause surface cracking, binder migration, or uneven porosity, affecting battery performance (such as ion conductivity, bonding strength) and production efficiency.

-

Difficult maintenance: Organic solvents like NMP need to be recovered through condensation, and the recovery equipment consumes high energy and is complex to maintain.

-

Large equipment footprint: Traditional ovens are bulky with uneven heat distribution, further exacerbating energy consumption issues.

Laser Heating Drying Solution

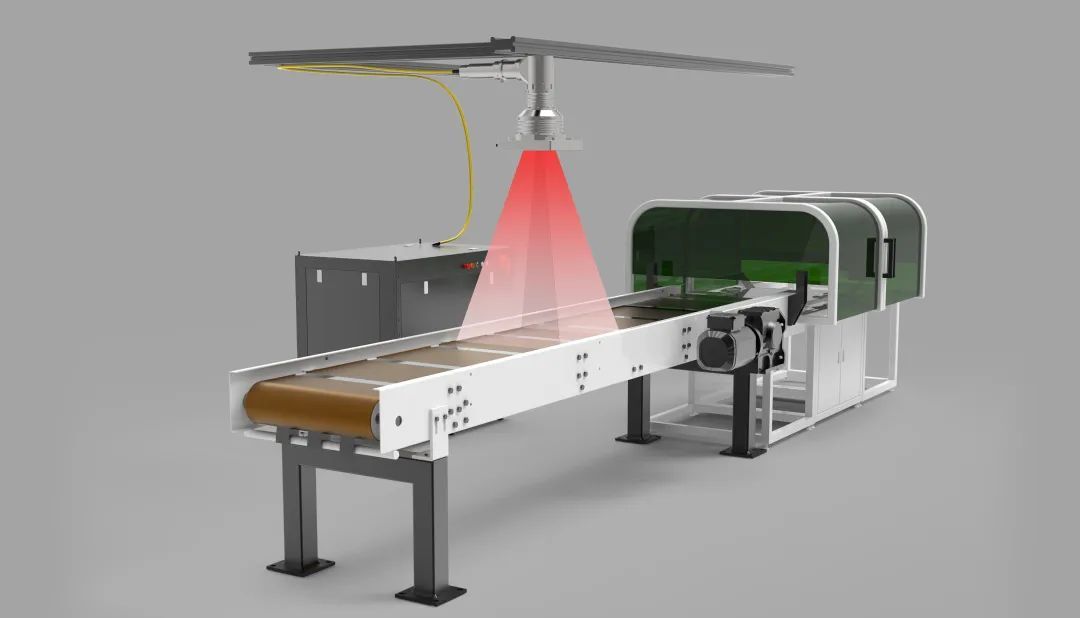

Using direct semiconductor lasers combined with large-area rectangular beam lenses to replace traditional convection drying can effectively solve these problems!

Direct Semiconductor Laser + Large-Area Rectangular Beam Lens Solution

-

High production efficiency: After homogenization and shaping, the laser directly irradiates the electrode sheet, drying the moisture in the slurry in a very short time;

-

High energy utilization: The electro-optical conversion efficiency of direct semiconductor lasers exceeds 55%, resulting in high energy utilization and greater energy savings;

-

Small footprint: The equipment occupies a small area, effectively saving factory space;

-

Simple operation and maintenance: The laser can be turned on and off as needed, allowing maintenance with power off at any time, and no preheating is required when starting.

Practical Application Cases

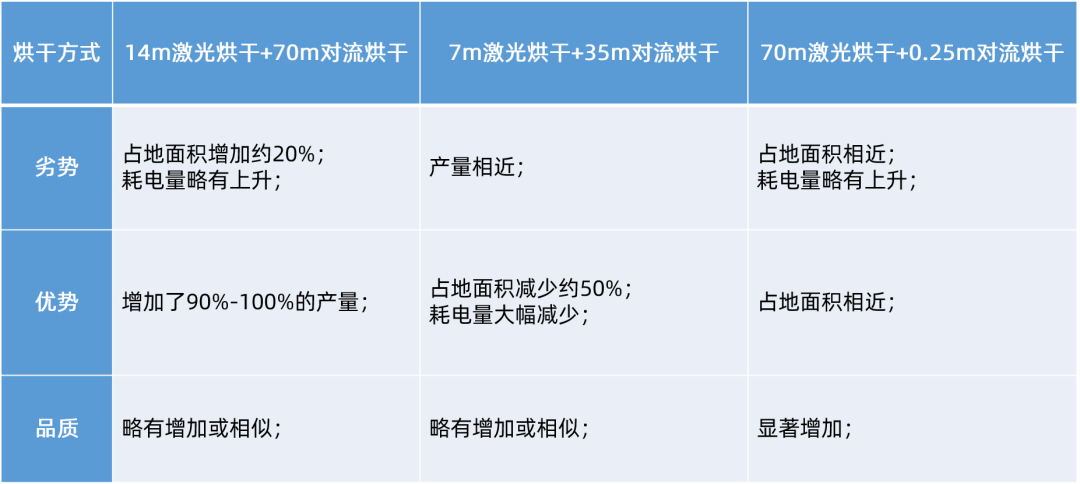

In lithium battery drying, directly replacing oven convection drying with laser drying yields good results but at a higher cost. In practice, a hybrid approach of laser drying plus oven convection drying is often used, modifying existing production equipment to achieve cost reduction and efficiency improvement. Taking the original 70m oven convection drying production line as an example:

Hybrid Laser Drying Process

After modifying the original production line:

-

The hybrid laser drying process can reduce the drying operation cost (including labor and maintenance) of battery electrodes by nearly 30%.

-

The hybrid laser drying process can reduce the drying footprint of battery electrodes by nearly 50% (under the same output).

-

Due to the low equipment footprint and efficient energy input (energy consumption) of the laser-based drying system, about 20% capital expenditure savings can be achieved.

-

By integrating large-area and uniform direct semiconductor laser spots, the quality of electrode drying can be improved.

Broad Industry Application Prospects of Laser Heating

Besides the new energy industry, high-power laser heating/drying has huge application potential and market space in aerospace, coating, and textile industries due to its advantages of high efficiency, low energy consumption, high space utilization, precise controllability, and uniform heating.

Aerospace

With the advent of the industrial lightweight era, industries such as aerospace and automotive will choose high stability, high strength, and lighter composite materials as the preferred materials for manufacturing product components. Among them, the use of thermoplastic composites has become a hot topic in the aerospace lightweight trend.

High-Performance Thermoplastic Prepreg Drying: The carbon fiber reinforced thermoplastic prepreg production line mainly consists of unwinding devices, impregnation devices, drying devices, and winding devices. The unwinding device is responsible for unrolling the carbon fiber fabric, the impregnation device uniformly coats thermoplastic resin on the carbon fiber fabric, the drying device can evaporate solvents in the prepreg through laser heating/drying, and finally, the winding device rolls up the finished prepreg. These devices work together to achieve efficient production of carbon fiber thermoplastic prepreg.

Preheating for Stamping Molding: Thermoplastic composite stamping molding faces issues such as high preheating temperature and uneven internal and external heating. Laser, with its high energy density and uniform heating, can solve this problem. The laser heating system can be equipped with temperature sensors and PID control to achieve constant surface temperature heating, ensuring uniform heating of inner and outer layers.

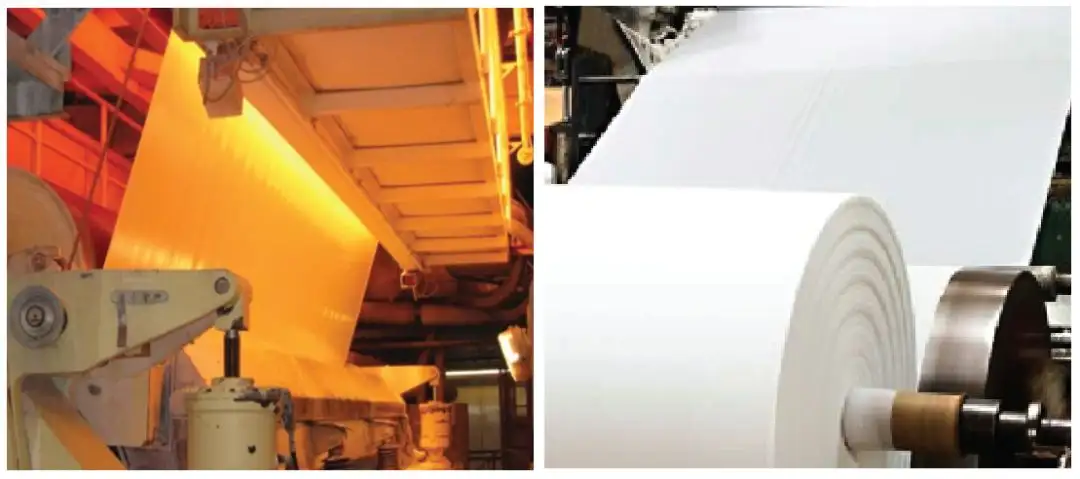

Coating and Textile Industry

The drying of paint, fabrics, paper, and other materials can fully utilize the characteristics of lasers. Due to the strong penetration of lasers, they effectively penetrate inside the drying materials, enabling gradual drying from the innermost layer to the outer layer. Because of wavelength matching, the moisture and solvents inside the drying materials evaporate first, resulting in better drying effects and effectively improving the surface quality of paint and fabrics.

Multiple product options available to help improve quality and efficiency of laser heating.

To meet laser heating demands, Changguang Huaxin has launched a series of 12KW, 20KW, and 32KW direct semiconductor lasers equipped with matching optical lenses, capable of achieving uniform heating. These products feature high efficiency, low energy consumption, high space utilization, precise controllability, and uniform heating, helping to enhance the quality and efficiency of laser heating!

Recommended Reading