High Power Narrow Spectral Width: 780nm Broad Stripe DFB Laser Power Breaks Through 10W

12/30

2024

In today's rapid development of laser technology, high-power and narrow spectral width lasers have become core demands in many scientific and industrial fields. Recently, a product developed by the CTO of Changguang Huaxin and Professor Wang Jun's research team at Sichuan University 7 has achieved a major breakthrough with an 80nm wide stripe distributed feedback (DFB) laser, with continuous output power exceeding 10W at room temperature. 。 This research result was published in the authoritative photonics journal "IEEE Photonics Journal". , It demonstrates the team's significant progress in high-performance laser design.

Research Background

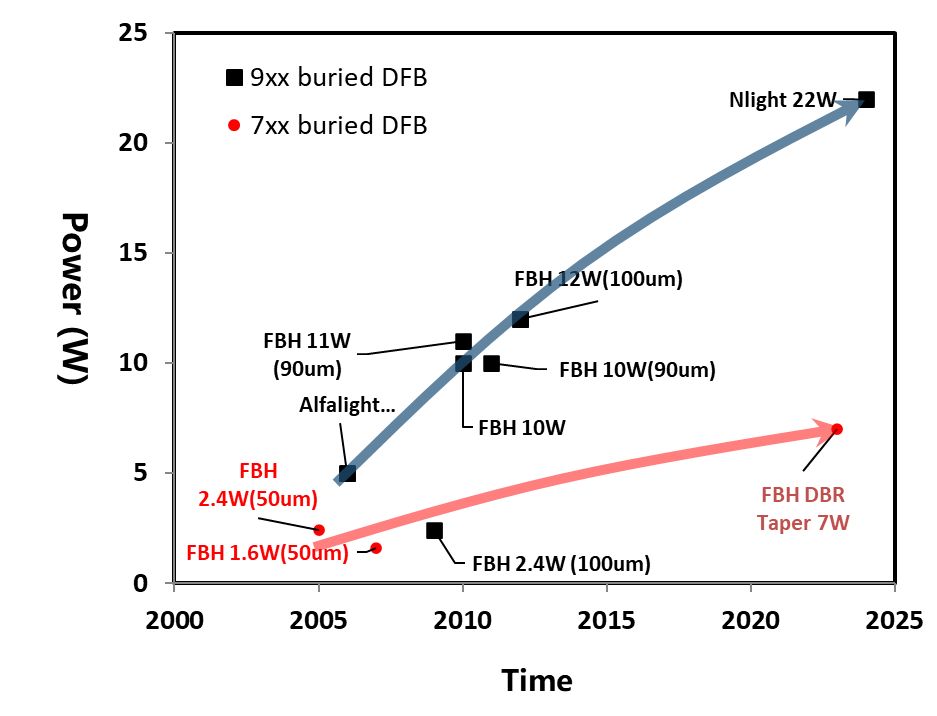

The 780 nm laser is a key pump light source for alkali metal vapor lasers (DPAL), with wide demand in precision science, industrial processing, and defense fields. However, traditional Fabry-Pérot (FP) lasers, although high in power, have too wide spectral width and poor wavelength stability, making it difficult to meet application requirements. Distributed feedback (DFB) lasers, with embedded Bragg gratings, can achieve narrow spectral width and good wavelength stability, making them an ideal choice. However, many technical challenges remain in achieving both high power and narrow spectral width simultaneously. The development history of DFB lasers is shown in Figure 1. Compared to 9xxnm devices, the power development of 7xxnm chips is relatively lagging, mainly due to market demand and material limitations. The issues to be solved are power enhancement and growth of built-in gratings. Reports on 780nm wide-stripe DFB lasers are rare. In 2005, the Ferdinand-Braun Institute (FBH) designed a 50um wide 780nm DFB laser with a power of 2.4W, which remains the highest power for 780nm DFB lasers to date. For pumping alkali metal laser systems, wide-stripe DFB lasers operate in multiple side modes, causing inevitable spectral broadening, but they can provide ten times the output power of RW devices. Therefore, developing high-power wide-stripe 780nm DFB lasers is crucial, bringing new possibilities for scientific and industrial applications.

Figure 1 Development history of 7xxnm and 9xxnm DFB lasers

Research Highlights

Professor Wang Jun's research team from the School of Electronic Information at Sichuan University and Suzhou Changguang Huaxin Optoelectronics Technology Co., Ltd. focused on the 780 nm wavelength, deeply studying factors limiting the output power of wide-stripe DFB lasers and overcoming multiple technical difficulties such as grating design and material growth. They designed a DFB laser based on InGaAsP/InGaP materials. As shown in Figure 1, continuous output power exceeding 10W was achieved at room temperature, with a spectral linewidth (FWHM) less than 0.5 nm, capable of effective operation over a wide current and temperature range.

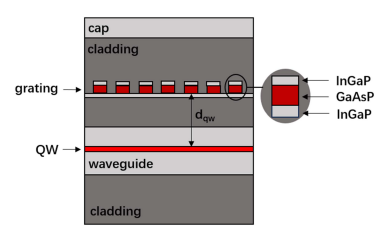

Figure 1 Epitaxial structure and grating layer sequence of the 780nm wide-stripe DFB laser

01|Optimized Grating Design

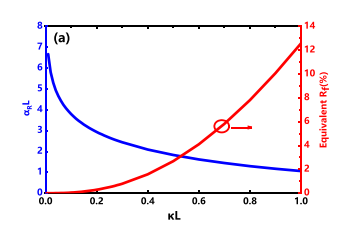

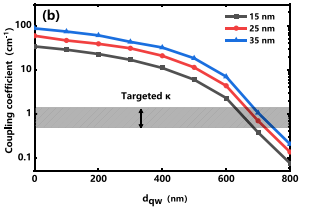

The research team constructed a grating analysis model based on coupled mode theory (CMT). By adjusting the grating coupling strength (κL controlled between 0.4-0.6) and the relative position of the grating to the quantum well, the calculation results shown in Figure 2 indicate that a smaller grating coupling coefficient increases the proportion of external coupling light, thereby improving power and efficiency. A more distant grating position significantly reduces optical loss and carrier recombination effects, ensuring high output power and low voltage.

Figure 2 (a) Variation of resonator loss of the DFB laser with grating coupling strength and relationship between equivalent FP front cavity reflectivity and grating coupling strength. (b) Relationship between grating coupling coefficient and distance from grating layer to active region and grating thickness.

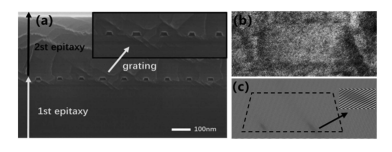

02|Material and Process Innovation

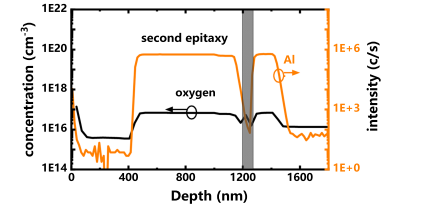

The grating region uses a low-loss, low-stress three-layer InGaP/InGaAsP/InGaP structure, avoiding grating absorption and defect issues caused by stress in traditional materials (such as GaAsP). The optimized secondary epitaxial process further reduces interface oxygen contamination, lowering oxygen content to the 1E16 level, greatly improving device efficiency and reliability.

Figure 3 (a) Cross-section of DFB in the epitaxial direction and scanning electron microscope (SEM) image of the grating, marking the start of secondary epitaxy. The inset shows an enlarged view of the grating. (b) Transmission electron microscopy image of the InGaAsP grating, (c) high-resolution image after Fourier transform.

Figure 4 SIMS spectra of O and Al, with Al as the marker layer.

03|Outstanding Performance

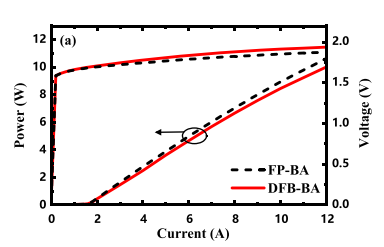

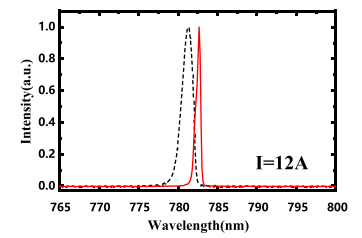

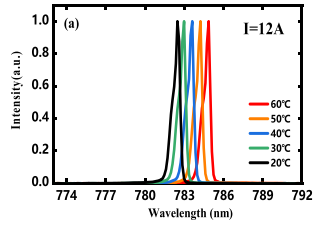

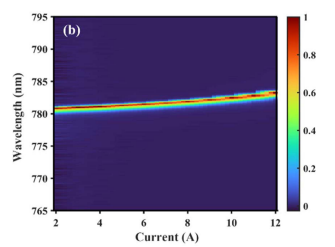

The researchers tested the device performance at 12 A current and 20 °C temperature control. As shown in Figures 5 and 6, the laser achieved continuous output power exceeding 10 W, with spectral width (FWHM) less than 0.5 nm. This power level sets a record for 780 nm band DFB lasers, while maintaining good wavelength locking characteristics over a wide current and temperature range.

Figure 5 (a) Performance comparison of 780 nm DFB-BA laser (solid line) and FP-BA laser (dashed line) tested under the same vertical design at a heatsink temperature of 20°C. (b) Spectral graph at 12A current.

Figure 6 (a) Spectral characteristics of the DFB laser at 12A over a temperature range of 20°C to 60°C. (b) Spectral graph of the DFB laser at 20°C under continuously varying current, with intensity shown in false color.

Summary and Outlook

In summary, the team has set a new benchmark for the development of high-power, narrow spectral width lasers. They will further optimize the design in the future to meet broader industrial and scientific research needs. Additionally, the technical methods of this research can be extended to laser designs in other wavelength bands. The application prospects of high-power narrow spectral width lasers are undoubtedly broad. From scientific instruments to industrial production and medical equipment, they will help multiple fields achieve technological breakthroughs.

Recommended Reading