The renowned international semiconductor industry magazine "Semiconductor Today" featured a column reporting on Changguang Huaxin's VCSEL efficiency progress.

12/30

2024

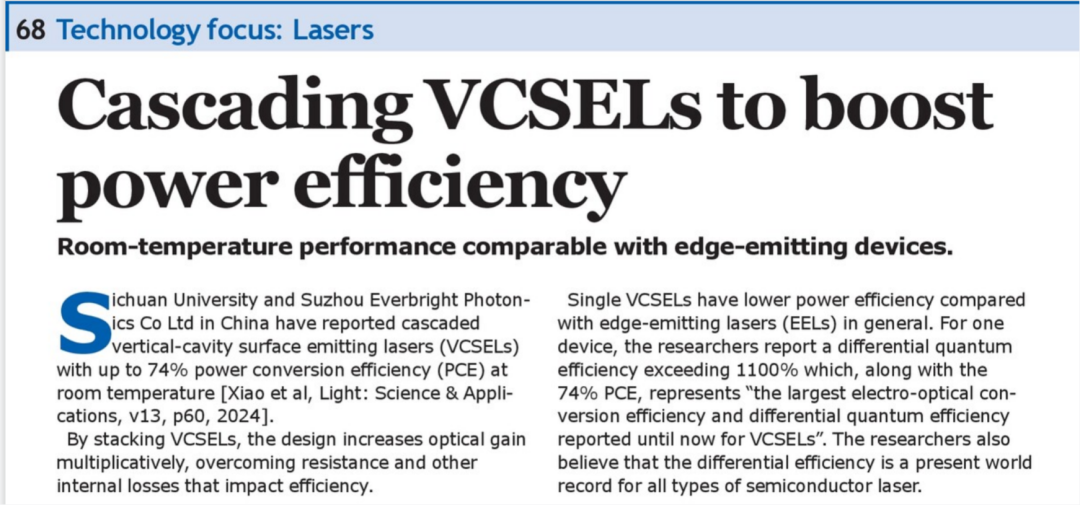

The internationally renowned semiconductor industry magazine "Semiconductor Today" featured a column report on the achievement of the "Cascaded VCSEL: A Breakthrough in Power Efficiency - Room Temperature Performance Comparable to Edge-Emitting Devices" led by Professor Wang Jun from Sichuan University and Suzhou Changguang Huaxin research team.

"Semiconductor Today," headquartered in the UK, is a well-known international semiconductor industry magazine and website, focusing on reporting significant research progress and the latest industry trends in the global semiconductor field, with strong industry influence.

The original translation is as follows:

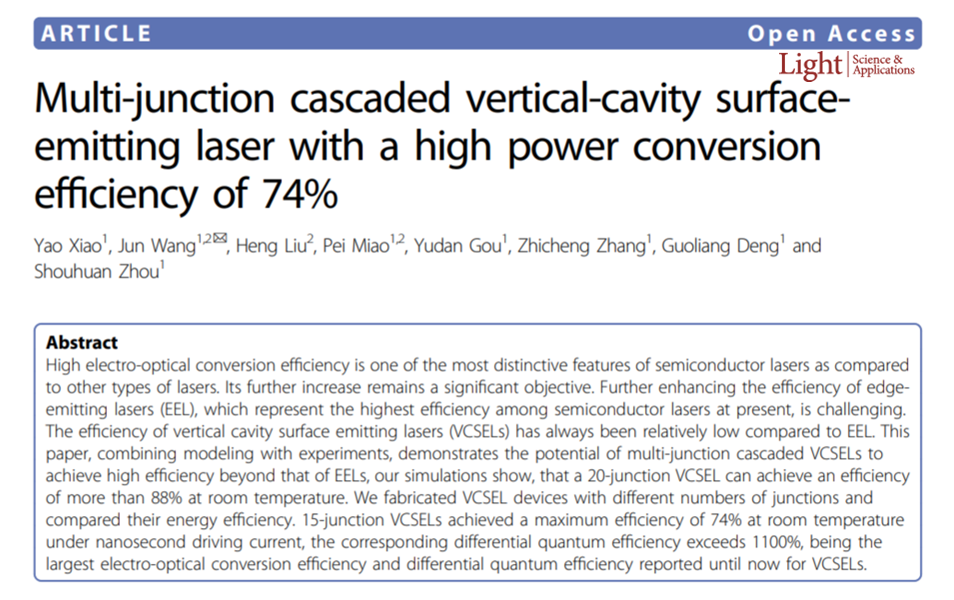

Sichuan University in China and Suzhou Changguang Huaxin reported a cascaded vertical-cavity surface-emitting laser (VCSEL) achieving a power conversion efficiency (PCE) of up to 74% at room temperature. [Xiao et al, Light: Science & Applications, v13, p60, 2024]

By stacking VCSELs, this design achieves a multiple increase in optical gain, effectively overcoming internal losses such as resistance and other efficiency-limiting factors. The overall power efficiency of single-junction VCSELs is lower than that of edge-emitting lasers (EELs). According to the researchers, the differential quantum efficiency of a single VCSEL unit exceeds 1100%, combined with a 74% PCE, considered the "highest reported electro-optical conversion efficiency and differential quantum efficiency" in the VCSEL field to date. This differential efficiency is a world record among all current semiconductor lasers. This performance improvement provides an effective solution to the energy consumption issues of VCSELs in future widespread applications. High power is also particularly important for long-range mapping in time-of-flight LiDAR. Suzhou Changguang Huaxin Optoelectronics Technology Co., Ltd., established in 2012, is dedicated to the research and development of high-power diode laser chips, high-efficiency LiDAR, 3D sensing, high-speed optical communication, and related optoelectronic systems.

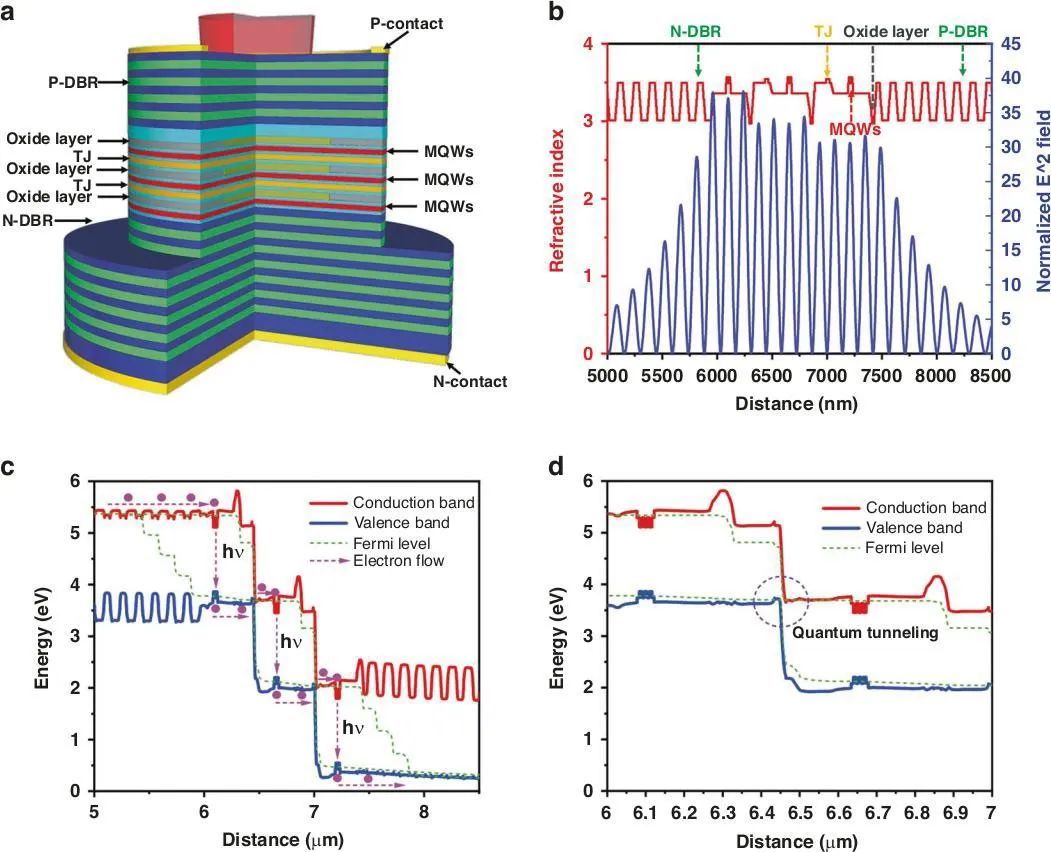

Figure 1. a Structural schematic; b Refractive index distribution and standing wave optical field distribution; c Active region band structure of triple-junction VCSEL under bias; d Band structure of tunnel junction under bias.

The cascaded VCSEL design (see Figure 1) includes an N-type distributed Bragg reflector (N-DBR), P-type DBR, multiple quantum wells (MQWs), oxide layer, and tunnel junctions (TJs). The design goal is to place the quantum wells at the peak of the standing wave optical field, while positioning the oxide aperture and tunnel junctions at the nodes. When the quantum wells are located at the maximum optical field intensity, the coupling efficiency between carriers and photons can be enhanced, thereby increasing optical gain. Placing the tunnel junctions at the nodes reduces losses caused by free carrier absorption.

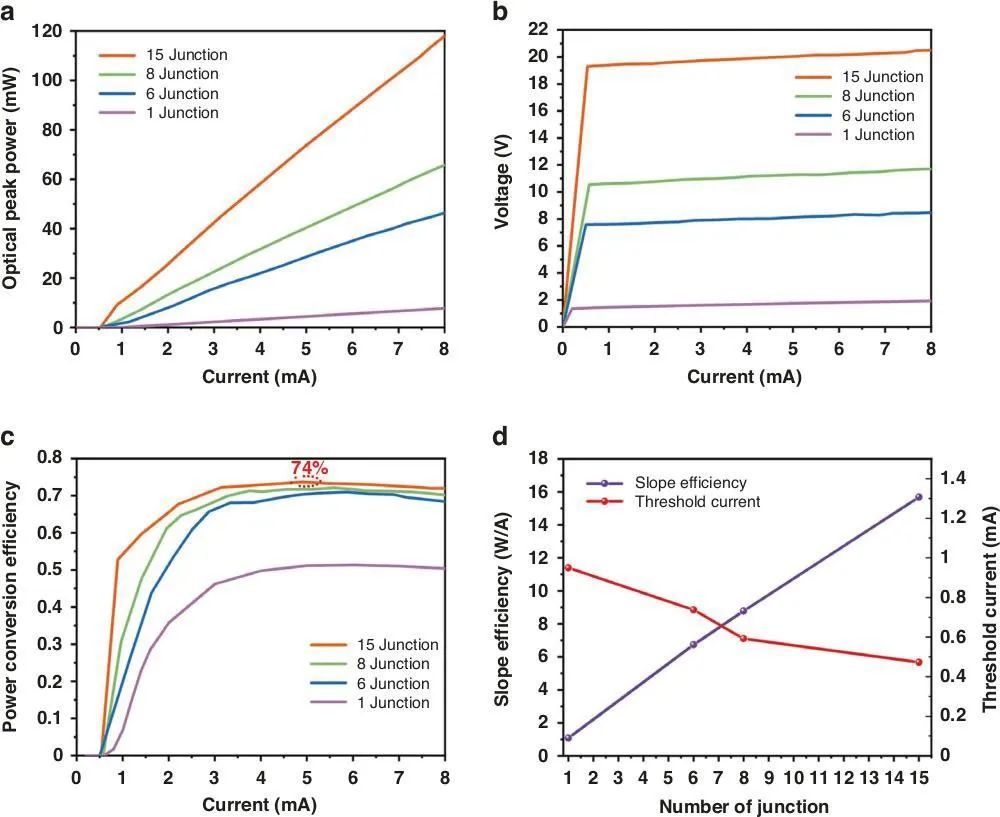

Figure 2. Performance of VCSEL cascades with different junction numbers: a, b Optical output power, current, and voltage (L-I-V); c Power conversion efficiency (PCE) for each junction number; d Slope efficiency and threshold current.

The device was fabricated using metal-organic chemical vapor deposition (MOCVD) technology. The DBRs use aluminum gallium arsenide (AlGaAs) alloy layers of different compositions. The quantum wells are 7nm indium gallium arsenide (InGaAs) with 6nm gallium arsenide phosphide (GaAsP) barriers. The MQW structure contains three quantum wells. The oxide layer is 20nm AlGaAs, and the tunnel junction (TJ) consists of heavily doped 15nm gallium arsenide (GaAs). The oxide aperture is formed by oxidizing high aluminum content AlGaAs material exposed to a high-temperature, high-humidity environment after mesa etching, with an aperture of 10 μm. The passivation layer is plasma-enhanced CVD deposited silicon nitride (Si3N4). The fabricated device was tested under 20ns pulses with a 0.1% duty cycle (50kHz). The 15-junction VCSEL achieved a peak power of 100mW at 7mA injection (see Figure 2). Its maximum electro-optical conversion efficiency, slope efficiency, and differential quantum efficiency were 74%, 15.6 W/A, and over 1100%, respectively. The turn-on voltage of the 15-junction device is 19V, which is considered advantageous for short-pulse and high-modulation-rate applications. The researchers explained: "Compared to high current signals, high voltage signals are more suitable for generating extremely short pulse widths and higher modulation rate signals." Although the top DBR reflectivity decreases with more junctions in the VCSEL, the threshold current shows a decreasing trend. The researchers noted that optimizing the top DBR reflectivity may further reduce the threshold current.

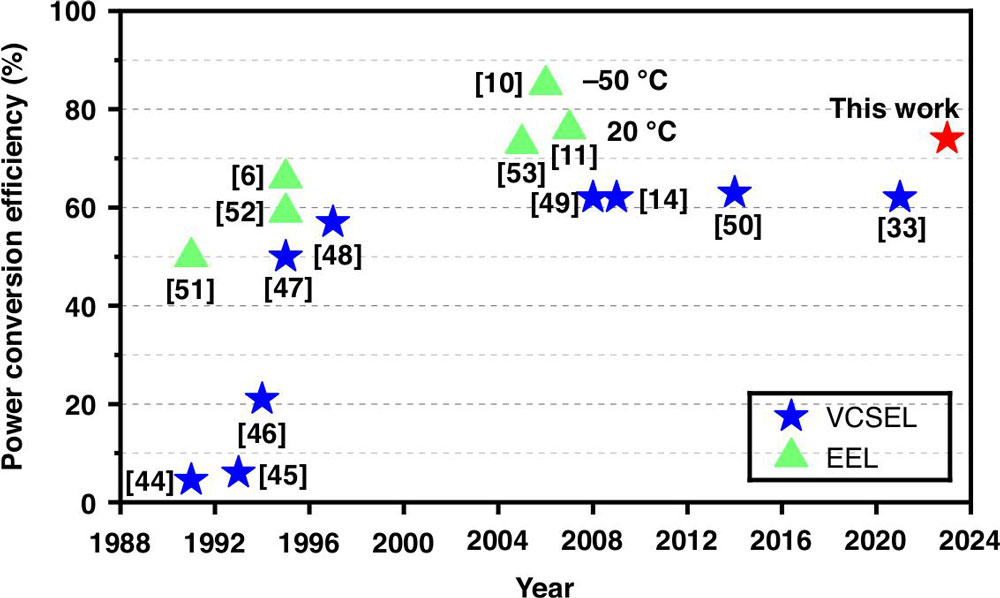

Figure 3. Summary of power conversion efficiency of VCSELs and edge-emitting lasers.

The far-field spot shows that the divergence angle increases with the number of junctions. The divergence angle of the six-junction cascaded VCSEL reached 28.8°. A larger divergence angle is unfavorable in many application scenarios; therefore, existing multi-junction VCSELs for LiDAR typically reduce the number of oxide layers to decrease the divergence angle. In a 2022 study, we reported reducing the divergence angle of an eight-junction VCSEL to 18° under short-pulse drive current by optimizing the oxide layer design.[1] These devices emit in the wavelength range of 940–950nm. As the number of junctions increases, the number of excited modes also increases. Based on power consumption analysis, the main reason for the increase in power conversion efficiency with more junctions is the reduction of Joule heating and internal losses caused by free carrier absorption. Comparing the 15-junction device with other reported semiconductor lasers (Figure 3), this not only significantly improves the efficiency of VCSELs over the past 20 years but also brings its room temperature performance basically to the highest power conversion efficiency level of EELs. Although EELs achieve a PCE of 86% at low temperatures, their room temperature PCE is 76%, a level comparable to the 74% performance of the 15-junction VCSEL.

[1] High performance multi-junction VCSELs for LiDAR applications. in Proceedings of SPIE 12020, Vertical-Cavity Surface-Emitting Lasers XXVI 1202005 (SPIE, 2022).

Original link:

https://www.semiconductor-today.com/news_items/2024/mar/sichuanuniversity-140324.shtml

Recommended Reading