Everbright’s 60kW 808nm macro-channel stacked array module wins the OFweek Cup Best Diode Laser Technology Innovation Award!

08/06

2025

On July 31, the "Vico Cup · OFweek 2025 Laser Industry Annual Selection" was held in Shenzhen, Changguang Huaxin 60kW 808nm High-Efficiency High-Brightness Macro-Channel Semiconductor Laser Stack Module Won the Best Semiconductor Laser Technology Innovation Award!

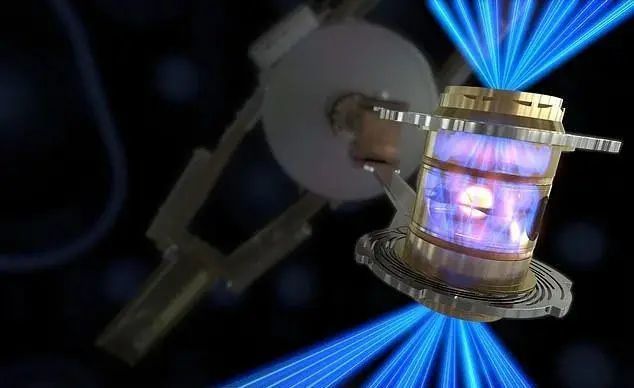

Laser Nuclear Fusion

Laser nuclear fusion is a highly promising technology capable of solving energy problems and has always been a key research and development project for countries worldwide. The core component of laser nuclear fusion, the neodymium glass laser, places high demands on the pump source's power, beam quality, stability, and cost. Changguang Huaxin has recognized this market demand and developed a 60kW 808nm high-efficiency high-brightness macro-channel semiconductor laser stack module, and has participated in domestic and international laser nuclear fusion related projects.

60kW 808nm Macro-Channel Stack Module

The awarded 60kW 808nm high-efficiency high-brightness macro-channel semiconductor laser stack module product adopts the most advanced technologies in chip design, epitaxial growth, bar packaging, and optical shaping. Under quasi-continuous mode, a single bar outputs 500W power, with a total product power reaching 60kW. The emitting surface size is only 153.5mm✖10mm, and the electro-optical efficiency reaches 70%. It not only achieves internationally leading performance indicators but also strongly promotes the development of laser nuclear fusion applications.

Innovations

01. Adopts high electro-optical efficiency epitaxial structure design, high fill-factor bar structure design, and efficient heat dissipation packaging technology, achieving an electro-optical efficiency of up to 70%;

02. Uses stripe mirror beam combining technology, eliminating 74% dark zones, stacking 120 bars within a 153.5mm size, increasing power density by 99%;

03. Modular design allows this product to be used as a unit module for more spatial stacking combinations, facilitating customer applications and reducing maintenance costs.

Changguang Huaxin

Changguang Huaxin is dedicated to the research and production of semiconductor laser chips. Its core technologies cover the most critical areas of the semiconductor laser industry, overcoming long-standing technical challenges in epitaxial growth, cavity surface treatment, packaging, and fiber coupling. It has established a fully independent and controllable IDM process platform and mass production line, making it one of the few IDM semiconductor laser companies globally with key process production capabilities such as 6-inch line epitaxy and wafer manufacturing.

☑ 2-inch, 3-inch, and 6-inch three mass production lines;

☑ Edge-emitting EEL and surface-emitting VCSEL two major product structures;

☑ Five major material systems: GaAs (Gallium Arsenide), InP (Indium Phosphide), GaN (Gallium Nitride), SiC (Silicon Carbide), SiPho (Silicon Photonics);

The company adheres to the development strategy of "one platform, one pivot, horizontal expansion, vertical extension," with semiconductor laser chips as its core competitiveness. It horizontally expands coverage from visible light, near-infrared, mid-infrared to long-wave, and vertically extends the "N+1" sectors, promoting photonic technology to empower industrial lasers, sensors, optical communications, laser display and lighting, laser medical aesthetics, and other industries. China's laser chip, illuminating a better life!

Recommended Reading